Torrox ensures equipment is designed and built to meet the mine site’s specific needs. We take pride in providing personalized technical solutions. Click on the equipment to read more information.

- + Conveyor Drive Systems

-

- Compact drive heads designed for mining use, up to 1200 HP

- Skid mounted, roof hung, or fixed to foundation

- Modular construction; easily upgraded in both speed and power

- Engineered to maximize interchangeability of parts

- Engineered systems up to 8,000 HP

- + Loop Take-Ups and Belt Storage Units

-

- Automatic and manual tensioning systems: gravity, electric, hydraulic, and pneumatic

- Up to 800m of belt storage capacity

- Quick addition and extraction of belt in extensible applications

- + Tail Ends

-

- Standard and low profile return ends

- Impact loading sections with idler sets or impact bars

- Mobile type, either skid or track mounted

- + Discharge Ends

-

- Integral to the drive with adjustable height and length

- Remote mounted to the roof or floor

- + Transfer Chutes

-

- Engineered chutes specifically designed for each application

- Dust tight or open top

- Replaceable wear liners for extended life

- + Idler Sets, Rollers, Pulleys, and Drums

-

- Standard frame with fixed, garland, or vari-trough idler sets

- Large diameter, heavy duty

- Sealed for life sealing elements

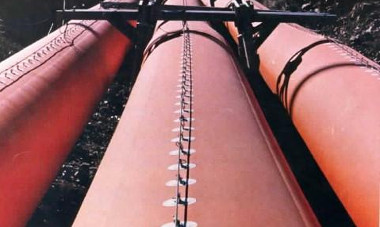

- + Conveyor Belting

-

- FenaplastTM Solid-Woven, PVC impregnated

- PVC or nitrile rubber covers

- Fire resistant and anti-static properties to CSA M422-M14

- Diamond Edge belting to reduce edge stranding, increase product life

- iBelt tracking system to manage inventory and maximize product utilization

- Hi-Vis covers in a variety of colors for safety and product life monitoring

- Design enhancements for extensible conveyors

- + Fluid Couplings

-

- Smoothest acceleration of the largest masses

- Load free start-up and run-up of the motor

- Torque limitation during start-up

- + Ancillary Equipment

-

- Maintenance stations up to 500m of belt

- Belt winders up to 500m of belt

- Belt cleaners

- Fines conveyors

- Emergency stop systems

- + Feeder Breakers and Belt Feeders

-

- Low profile underground machines

- 2,000 tph production

- Fracture materials up to 30,000psi

- In-pit units for 30,000 – 40,000psi materials

- Mobile belt tail ends

- + Jumbo Drill

-

- Hydraulic rotary or hydraulic percussion rotary drifters

- Single or twin boom

- Dual powered, diesel hydraulic, or electric hydraulic

- Face coverage up to 18.9m x 12.2m

- + Roof Bolters

-

- Bolts up to 11ft long

- Patented “Centra-Stinger” placement

- Hydraulic rotary or hydraulic percussion rotary drifters

- Single or twin boom

- Dual powered, diesel hydraulic, or electric hydraulic

- + Scaler

-

- Reach up to 48.5ft

- Scaling pick provides high breakout force for efficient scaling

- + Utility Vehicle

-

- Configurable bed options:

- ANFO Truck

- Fuel & Lube Truck

- Man Lift

- Scissor Lift

- Telescoping Crane

- 6-person Quad Cab

- 9-person Personnel Carrier

- Dump Truck

- Flatbed Truck

- Four wheel steering for enhanced maneuverability and turning radius

- Oscillating articulation joint allows mounting of all 4 jacks on rear chassis

- Battery powered for zero emissions

- Climbs 25% grade

- + Mining Grid, Rock Mesh, & Roof Mats

-

- Strong, lightweight, flexible, and corrosion-resistant polymeric grid

- Safer, faster, installation than chain link or welded wire mesh

- Flame retardant

- + Ventilation Ducting & Curtains

-

- Ventilation ducting (positive and negative pressure, spiral)

- Strip or Velcro strip curtains

- Brattice curtains

- + Miscellaneous

-

- Hoists and winches (electric, pneumatic, or hydraulic)

- Mining chains (round link up to 32mm, DIN spec)

- Cutting heads, drill bits, custom designed

Field supervision or installation of systems or components is available as required.

Torrox has expertise in all aspects of supply chain management including import/export, transportation, storage, just-in-time inventory management, multi-year supply contracts, etc.